Consulting

In the last decade we have been bombarded with dramatic changes in our business and economic environment. Companies across all industries have faced the challenges of a changing workforce and increased customer demands. Toyota Material Handling Systems and its operating companies are committed to helping our clients stay ahead of the trends and be able to better predict, respond and adapt to the changing business environment. We do this by partnering with them to build a sustainable supply chain that is flexible enough to quickly adjust to changing market demands and ultimately create a significant competitive edge.

Our Consultants are comprised of industry thought leaders with a vast array of experience across all industries. We take a brand agnostic approach to all of our consulting engagements, which allows us to provide the best-in-class solutions to our clients without being bound by any manufacturer or distributor agreement. Unlike other consulting firms, we also implement all of the solutions we provide. This allows us to provide clients with a more pragmatic and comprehensive product that has real-world applicability.

Our Consulting solutions include:

- Network Design

- Distribution Facility Design

- Labor Management

- Fleet Optimization

- Conveyor System Design

- WMS Selection

- Slotting Analysis

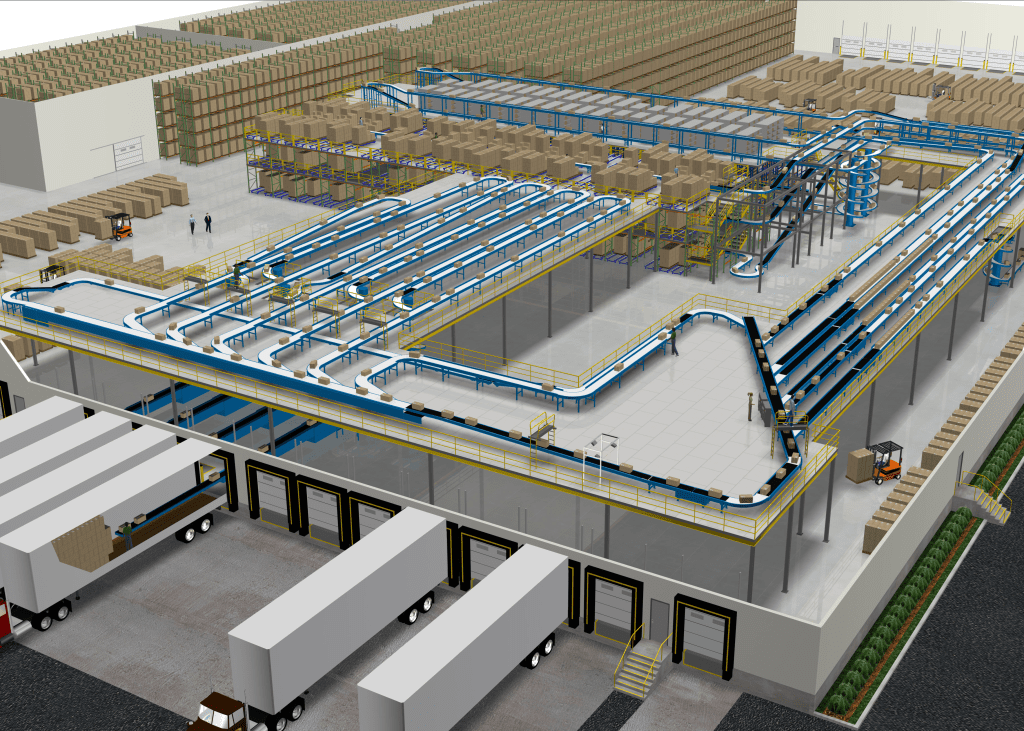

Material Handling Systems Design and Integration

In today’s supply chain the only thing that is constant is change. As our clients continue to grow, so do their system’s needs. Toyota Material Handling Systems and its operating companies not only provide all the equipment and technology you need to stay ahead of the curve, but we also ensure that all the material handling equipment in a facility works together as a unified, integrated material handling system. Our ability to tie technologies together in a properly designed system can help a company improve customer service, reduce inventory, shorten delivery time, and lower overall handling costs in manufacturing, distribution and transportation.

Technology Solutions Include:

- Order Fulfillment

- Goods To Person

- Sortation

- Picking Technologies

- WMS & WCS

- Automated Guided Vehicles

- Mobile Robotics

- AS/RS

- Automated Case Flow

- Vertical Lift Modules

- Conveyor Systems

- Custom Automation

- Industrial Controls

- Industrial Robotics

- RFID

- Storage

- Lift Trucks

Operational Excellence

Toyota Material Handling Systems and its operating companies understand the importance of ensuring our clients’ supply chains are operating at maximum efficiency long after they are implemented. Operational Excellence programs not only support the success of a total integrated supply chain solution, but they have proven to achieve results as a stand-alone program. Our proven methodology focuses on sustainable results.

Offerings cover a variety of areas, including:

- Change Management

- Workforce Planning and Forecasting

- Operator and Supervisory Training

- Compensation and Incentives

- Measurement – from Benchmarks to Engineered Labor Standards

- Continuous Measurement Improvement and Technology and Systems

- Fleet Management and Optimization

- Material Handling Maintenance Programs – Toyota Material Handling Systems has access to the entire Toyota Material Handling North America network, which includes 87 dealers, 328 locations and over 6,000 certified technicians with experience on all types of material handling equipment. This allows us to ensure your equipment is always up and running no matter your location.