Lean Management

Increasing Profit by Eliminating Waste

Out consultants will speed your journey to greater efficiency and sustained improvements.

Toyota Material Handling Systems has a team of experts to guide your transformation without interrupting production or customer service. A free Lean Assessment will be performed to illustrate where rapid gains can be made.

Lean Management Assessments

How It Works

We deliver improvements by developing people. This is a partnership where we train, demonstrate, then coach your people how to eliminate waste.

Introduction

We start with a conversation about your goals. We want to understand your pain points and how we can address them.

Questions include:

- Past and future challenges?

- How do you measure success?

- Historic improvement efforts?

- Customer feedback?

- Regulatory constraints?

Assessment

This free assessment at your facility will show our commitment to adding value before any formal agreement.

Assessments include:

- Identified waste

- Recommended actions

- Potential savings

Proposal

We collaborate with your leadership to define priorities, timeline, and budget that best suits the operation.

Contents include:

- List of deliverables

- Detailed Timeline

- Consultant availability

- Estimated project costs

- Requirements of on-site staff

Deployment

We collaborate with your staff through the whole process to ensure they can sustain improvements and continue your Lean Transformation after we’ve gone.

Solutions can include:

- Training

- Pilot projects

- KPI Dashboards

- Process Mapping

- Work Instructions

Lean Classes

How It Works

These are the classes we offer to build your team into a force of continuous improvement.

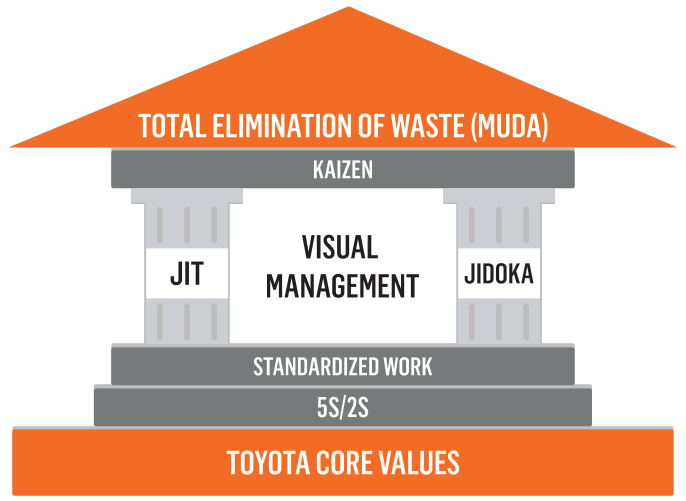

Lean Fundamentals

An explanation of the basic philosophy of the Toyota Production System with examples and in-class activities.

Details:

- Videos and case studies with opportunities for attendee participation.

- 8 hours

- Offered weekly

- For all levels of the organization

- Receive Lean Fundamentals Certification

Principles of 5S

Builds upon Lean Fundamentals How to evaluate and organize a work area for safety, cost reduction, and productivity.

Details:

- Videos and case studies with opportunities for attendee participation.

- 8 hours

- Offered weekly

- For managers, supervisors, team leads

- Receive Lean 5S Certification

Standardized Work

Builds upon Lean Fundamentals and 5S. Details exercises on how to create standardized work for value.

Details:

- Videos and case studies with opportunities for attendee participation.

- 8 hours

- Offered monthly

- For managers & supervisors Receive Lean 5S Certification

Download our Lean Management E-Book

Get insights and tips on the principles of Lean Management written by our own experts.