Operational Excellence

Toyota Material Handling Systems and its operating companies understand the importance of ensuring our clients’ supply chains are operating at maximum efficiency long after they are implemented. Operational Excellence programs not only support the success of a total integrated supply chain solution, but they have proven to achieve results as a stand-alone program. Our proven methodology focuses on sustainable results.

Offerings cover a variety of areas, including:

- Change Management

- Workforce Planning and Forecasting

- Operator and Supervisory Training

- Compensation and Incentives

- Measurement – from Benchmarks to Engineered Labor Standards

- Continuous Measurement Improvement and Technology and Systems

- Fleet Management and Optimization

- Material Handling Maintenance Programs – Toyota Material Handling Systems has access to the entire Toyota Material Handling North America network, which includes 87 dealers, 328 locations and over 6,000 certified technicians with experience on all types of material handling equipment. This allows us to ensure your equipment is always up and running no matter your location.

Toyota Material Handling Systems

Automated Guided Vehicle: Interview with Toyota Advanced Logistics

Presentations, Webinars, and Other Resources

Getting in to the E-commerce Game

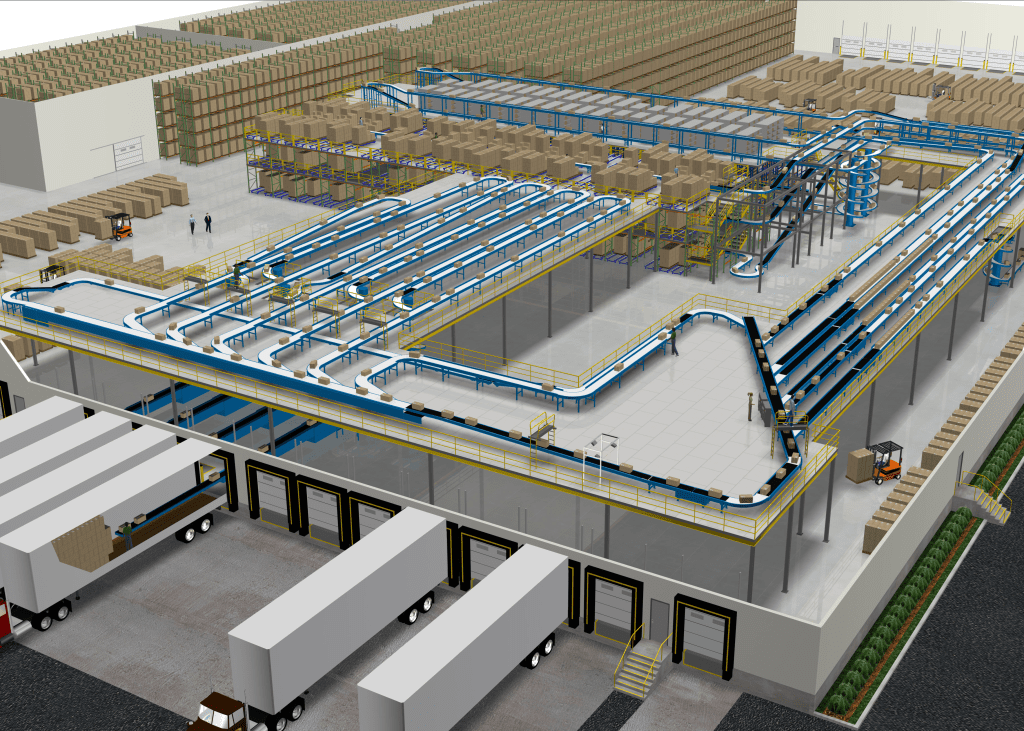

Are you trying to gain an advantage, shipping high volume e-commerce orders from a high SKU count inventory? Are you faced with significant fourth quarter peak demand? Do you want to understand how to reduce labor while enhancing outbound order quality? This case study-based presentation will demonstrate methods by which such achievements can be gained through careful application of automation and efficient, best practice procedures. VIEW PRESENTATION

How IoT is Revolutionizing the Supply Chain and What That Means for You

The Internet of Things (IoT) is a term first coined in the late 90s, but it made a minimal impact on the supply chain for many years. Move forward almost two decades, and advancements in the hardware and software powering IoT are now enabling revolutionary opportunities in the logistics, supply chain and material handling industries. From traditional cellular devices to self-balancing mesh networks, today’s IoT solutions offer detailed monitoring, communication, and analysis of assets inside your facilities and across the globe. Learn how IoT has evolved and how you can use it to create a more productive, cost efficient operation. VIEW PRESENTATION

Automation with Purpose: Tips for Maximizing Your Investment

To maximize productivity, minimize costs, and compete in a global marketplace, today’s distribution and manufacturing facilities are turning to advanced material handling automation. But for many small to medium size companies, getting started with automation can be daunting and expensive, and automation for small and medium size companies rarely looks the same as automation for large companies. Whether you have a single facility or several, we will show you the value of implementing the right hardware and software for your facility so you can maximize your investment and prepare your company for future growth. VIEW PRESENTATION